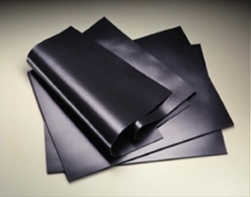

MJ May Material Specialists Inc. High Performance Polyurethane Rubber sheets and strips exhibit many of the properties of high performance rubbers and plastics, while maintaining the ability to be as soft as chewing gum or as hard as a bowling ball. It has the unique ability to return to its original shape and is extremely stable when exposed to temperature changes.

MJ May Material Specialists Inc. High Performance Polyurethane Rubber sheets and strips exhibit many of the properties of high performance rubbers and plastics, while maintaining the ability to be as soft as chewing gum or as hard as a bowling ball. It has the unique ability to return to its original shape and is extremely stable when exposed to temperature changes.

Our polyurethane is made in the USA of the highest quality, highest performing materials to the exact specifications your application requires. Polyurethane is used in applications where abrasion resistance, resistance to compression set, impact resistance, tear resistance, chemical resistance, or many other properties are desired. Polyurethane compounds possess an extraordinary combination of physical, mechanical, and environmental properties. Combining the outstanding properties of rigid plastic, metals, and rubbers, a superior viscoelastic polymer was born. It has the shock absorbing properties of rubber coupled with the tear resistance of plastic.

The most outstanding properties are:

- Excellent resilience

- Extra toughness and durability

- Very high load bearing and cut resistance

- Low compression set

- Very good impact resistance

- Excellent abrasion resistance

- Oil, solvent and water resistance

Polyurethane can be used in a temperature range from –20°F to +200°F.

Typical Properties

Color: Black

Temperature Range: –20°F to +200°F

Tensile Strength: 800 psi (40A), 4,100 psi (60A), 6,350 (80A), 5,500 psi (90A), 6,500 psi (95A), and 8,000 psi (75D)

Recommended for Outdoor Use: YES

Typical Applications

Applications include: high tension applications such as conveyor belts, high wear applications such as cutting surfaces, bumpers, and liners.

Form Available (from stock)

Sheet: 1/16” to 1-1/2” thick

Rod: 1/4” to 2” OD

Tubes: 1/4” to 1” ID / 7/8” to 2” OD

Durometers Available: 40A, 60A, 80A, 90A, 95A and 75D

MJ May stocks full sized sheets with and without adhesive backing. From these sheets, we can cut strips, die cut or waterjet cut parts to your exact specifications. Send us your design and we can provide your parts in short order from our state of the art converting facility and we have the in-house capabilities to modify these products so you receive the exact product you require with minimal lead times.